Quality control for CNC machined washers involves rigorous inspection processes to ensure high precision, consistency, and reliability. These processes include dimensional measurements, surface finish assessments, and material testing to verify that the produced washers meet or exceed industry standards. Advanced inspection equipment, such as coordinate measuring machines (CMM) and optical comparators, are employed to evaluate the accuracy and uniformity of the washers. Ensuring the highest quality of CNC machined washers is vital for maintaining the safety, performance, and longevity of various assembled products and structures.

CNC machined washers offer significant advantages in automated manufacturing, including precision, consistency, and adaptability. The computer-controlled process ensures tight tolerances and exact dimensions, resulting in superior performance and reduced wear on joined components. CNC technology enables rapid production of various washer types and sizes, catering to diverse industry needs. Automated manufacturing systems seamlessly integrate CNC machined washers, enhancing efficiency and minimizing human error. Overall, CNC washers contribute to streamlined production, improved product quality, and increased cost-effectiveness in modern manufacturing environments.

As a professional flat washer manufacturer, we specialize in manufacturing a wide range of high-precision washers and shims, designed to meet the stringent requirements of various industries. Our products, including flat washers, spherical washer sets, and custom shims, are engineered for superior performance, durability, and reliability. Utilizing advanced CNC machining technology, we ensure tight tolerances and consistent quality. Explore our comprehensive selection to find the perfect solution for your mechanical and structural applications. Trust HHC Precision for all your washer and shim needs.

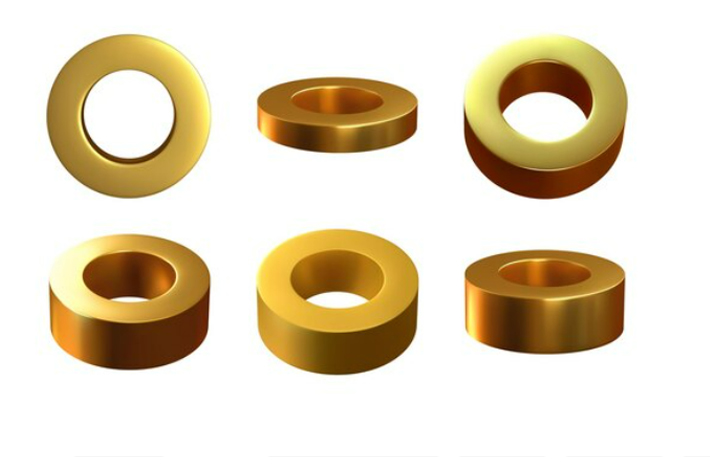

Flat washers are a common type of mechanical component characterized by a flat, circular appearance with a central hole. These washers play a crucial role in various engineering and manufacturing applications. Their primary applications include:

Load Distribution: Flat washers are used to uniformly distribute loads in bolts, nuts, and other fasteners, helping to reduce surface pressure and prevent deformation or damage to components.

Sealing and Leak Prevention: In pipeline connections, valves, and other liquid or gas systems, flat washers are employed to provide a sealing effect, preventing the leakage of liquids or gases and ensuring the reliability of connection points.

Shock Absorption: Flat washers can be used to attenuate mechanical vibrations or impacts, protecting components from the effects of vibration and shock and improving system stability.

Alignment Adjustment: During the assembly process, flat washers serve as alignment and adjustment tools, ensuring the correct gaps and positions between components.

Thermal Insulation: In heat-sensitive applications, flat washers function as thermal insulation materials, preventing heat conduction and ensuring the normal operating temperature of equipment.

Electrical Insulation: Flat washers act as insulation materials in electrical systems, preventing the flow of electric current and providing protection for electrical components.

Component Assembly: In the assembly of mechanical and electronic equipment components, flat washers are used to ensure the proper installation of fasteners and provide the required clamping force.