Machining processes for stainless steel CNC turning parts involve several steps, including selecting the appropriate cutting tools and feeds and speeds for the specific stainless steel grade. The turning process involves rotating the workpiece on a lathe while a cutting tool removes material from the surface. The process may also involve secondary operations, such as drilling, tapping, and threading, to produce a finished part. Machining stainless steel can be challenging due to its high hardness and strength, but CNC turning technology allows for precise and accurate production of complex parts. Overall, effective machining processes for stainless steel CNC turning parts require expertise and advanced equipment to ensure the quality and reliability of the final product.

Heat treatments can significantly impact the properties and performance of stainless steel CNC turning parts. Heat treatments involve subjecting the stainless steel part to specific temperatures and cooling rates to alter its microstructure and properties. Common heat treatments for stainless steel include annealing, quenching, and tempering. These treatments can improve the part's hardness, strength, and ductility, making it suitable for use in various applications. However, heat treatments can also cause distortion or cracking of the part if not performed correctly. Thus, proper selection and implementation of heat treatments are essential to achieving the desired properties and ensuring the quality and reliability of stainless steel CNC turning parts.

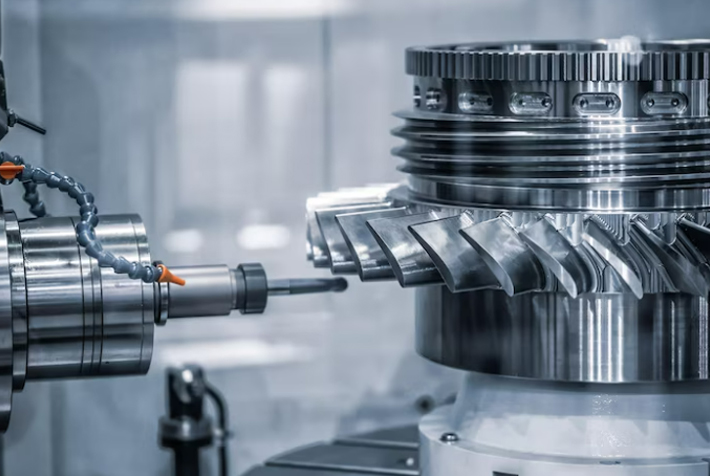

Stainless steel boasts excellent corrosion resistance, making it a commonly used and durable material in the hardware industry, particularly in humid, acidic, or alkaline environments. However, stainless steel's high hardness and relative density require more powerful machinery and cutting tools.

Due to the elevated hardness of stainless steel, selecting appropriate cutting tools is crucial to ensure efficient cutting. Controlling cutting speed and feed rate is also essential to prevent overheating and extend the lifespan of the tools. The machining process often involves the use of coolant to reduce cutting temperatures, minimize wear, and enhance processing efficiency.

Depending on the intended application, post-processing treatments such as annealing, pickling, or polishing may be necessary for stainless steel hardware products. These treatments aim to improve both performance and appearance.

After processing, stainless steel hardware components can be utilized in various applications, including gears, bearings, nuts, connectors, conductive elements, casings, automotive core components, automotive body parts, medical equipment components, aircraft structures and engine components, as well as electronic equipment components.

As a leading CNC turning parts supplier in China, HHC Precision combines decades of expertise and state-of-the-art manufacturing capabilities to deliver components that consistently exceed expectations. Engineered to meet the highest standards of quality and performance, our parts are crafted from premium stainless steel materials, ensuring durability and resistance to corrosion in diverse industrial applications. Whether you require prototypes or high-volume production, our commitment to quality ensures consistent performance and customer satisfaction.

Explore Our Range:

Browse our comprehensive selection of Stainless Steel CNC Turning Parts to find the ideal solution for your specific needs. Contact us today to discuss your requirements or request a quote, and experience the reliability and precision that define HHC Precision.