Quality control of stamping parts involves various measures and processes to ensure that the components meet the required specifications and standards. This includes using advanced inspection tools, conducting visual inspections, performing dimensional checks, and carrying out performance tests. Through rigorous quality control, stamping parts can be verified to meet customer requirements, improve product quality, and reduce defects, ultimately resulting in higher customer satisfaction and better business performance.

HHC Precision's stainless steel stampings are known for their superior strength, durability and corrosion resistance. Advanced stamping processes can produce complex shapes and designs to meet the needs of various industries such as automotive, aviation, electronics, medical and food processing. Features of stamping punching parts include:

High strength and durability: suitable for high loads and harsh environments.

Excellent corrosion resistance: withstands moisture, chemicals and high temperatures.

Precision manufacturing: meet customers' customized needs, ensure high quality and cost-effectiveness.

Using stamping parts in manufacturing offers numerous benefits, including high production efficiency, cost-effectiveness, and accuracy. Stamping parts can be produced in large quantities with minimal waste, resulting in lower production costs. They are also highly accurate, allowing for consistent quality and improved product performance. Additionally, stamping parts are versatile and can be customized to meet specific design requirements, making them suitable for a wide range of applications in various industries.

Strict Delivery Schedule: Strict adherence to delivery schedules is ensured. For stocked items, orders are immediately dispatched upon receipt, with options for sea, land, or air freight. For customized products, integrated design-to-manufacturing processes guarantee rapid delivery within 1-4 weeks.

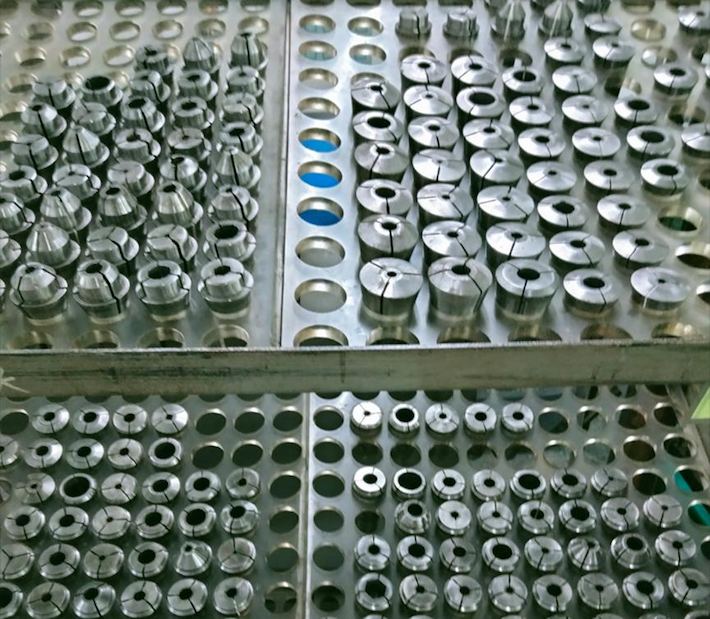

Quality Assurance: A systematic quality inspection system and 24-hour machines intelligent testing ensure product quality throughout the manufacturing process.

Efficient Production Processes: Our production processes are highly efficient, encompassing stamping, CNC machining, machining centers, stretching, electroplating, pickling, passivation, cleaning, grinding, assembly, and more. These processes enable us to provide high-quality services and competitive products.

Esteemed Veteran in Hardware Manufacturing: With over 23 years of experience and a production workshop spanning 33,000+ square meters, we have established ourselves as a trusted leader in the industry, boasting our own industrial park.

In the world of metal fabrication, two common processes, stamping and punching, play crucial roles in shaping materials for various applications. While they share similarities, understanding the key differences between stamping and punching is essential for manufacturers and engineers. This article delves into the nuances that set these processes apart, providing insights into when to use each method for optimal results.

Stamping:

Stamping involves the use of a die to shape and form metal sheets or strips. The die, typically made of hardened steel, contains the desired pattern or design. A press applies force to the material, causing it to take the shape of the die. This process is commonly used for creating intricate shapes, patterns, or logos on sheet metal.

Punching:

Punching, on the other hand, involves the removal of a portion of the material to create a hole or opening. A punch and die set is used, with the punch forcing its way through the material to create the desired hole or shape. Punching is particularly effective for producing simple and consistent holes in various metal components.

Stamping:

Stamping is favored for applications where intricate designs, patterns, or embossed features are required. It is commonly used in industries such as automotive, electronics, and appliance manufacturing for decorative or functional purposes.

Punching:

Punching is well-suited for applications where simple and consistent holes are needed, such as in the creation of brackets, panels, or components that require uniform openings. It is widely used in industries like construction, metal fabrication, and HVAC.

While stamping and punching share common ground in the realm of metal fabrication, the distinction lies in their specific applications and the outcomes they achieve. Stamping excels in producing intricate designs and patterns while punching is the method of choice for creating precise holes.

HHC (Haohaichang) offering a spectrum of order options to cater to diverse client needs. From customized sample prototyping to small, medium, and large-scale production, HHC provides end-to-end collaboration. HHC promises seamless integration services from sample validation to mass production.

1. Customized Sample Prototyping:

HHC recognizes the importance of prototype development in the product design and validation process. With a dedicated focus on meeting client specifications, HHC offers customized sample prototyping services. This stage allows clients to assess the feasibility, design, and functionality of their components before committing to larger production volumes.

2. Small Batch Orders:

For projects requiring limited quantities, HHC accommodates small batch orders with precision and efficiency. Small batch orders are ideal for initial market testing, ensuring that clients can introduce their products with minimal risk and optimal quality.

3. Medium Batch Orders:

As businesses expand, the need for medium batch orders arises. HHC seamlessly transitions from small to medium production volumes, providing the same level of attention to detail and quality assurance. This flexibility caters to the evolving demands of clients in various industries.

4. Large Batch Orders:

HHC's capabilities extend to large-scale production, catering to clients with substantial volume requirements. Leveraging advanced technology and a streamlined production process, HHC ensures the efficient and timely delivery of large batch orders without compromising on quality.

HHC's commitment to order flexibility sets it apart in the realm of metal fabrication. From customized sample prototyping to large-scale OEM stamping production volumes, HHC provides a seamless and comprehensive range of services. Clients can trust HHC to navigate every stage of the production process, ensuring that their unique requirements are met with precision and efficiency.

Determining the best materials for stamped products involves considering factors such as functional requirements, material characteristics, operating environment, and cost. For example, aluminum alloy 7075-T6 is commonly used in vehicle suspension systems, while 45# steel is often employed in vehicle transmission systems, and 304 stainless steel is frequently used for exhaust pipe measurements. Brass C26000 is commonly utilized in automotive radiators, and copper-nickel alloy C70600 is often found in braking systems, among others. We will provide the best solution recommendations based on the specific conditions of the customer's application.

Metal stamping, also known as pressing, is the process of forming metal sheets or strips into desired shapes and configurations using a stamping press and dies. This manufacturing process involves applying pressure to the metal workpiece, causing it to deform or displace, thereby creating the desired shape or pattern. HHC's stamping process includes techniques such as cutting, punching, bending, stretching, coining, and embossing.

When a single stamping operation cannot achieve the required shape or when the workpiece shape is highly complex, we employ progressive die stamping. Within a single die set, each station is equipped with one or several basic stamping processes to complete the processing of a specific part of the stamped workpiece. This involves a continuous sequence of operations including cutting, bending, punching, pressing, and forming.

We are based in Shenzhen and have our own industrial park in Huizhou. With 23 years of experience in the hardware manufacturing field, we have built a team of technical experts dedicated to continuous improvement and a team of experienced managers. Thanks to advanced equipment and institutional support, HHC is able to leverage its expertise in design and manufacturing in the hardware industry while ensuring high-quality products and services and generating reasonable profits. Therefore, we are confident in facing risks at any time. You are welcome to visit our company for inspection. A1 Building, Rongchang Industrial Park, No.440 Hedong Zone, Hengkeng, GuanLan, Longhua District, Shenzhen City, Guangdong Province, China

HHC produces a wide variety of stamped parts, including stretching-type, flange-type, small bracket-type, wiring terminal-type, fixing clip-type, spring plate-type, connector terminal-type, and terminal piece-type products. These are widely used in household appliance components, automotive components, new energy storage industries, consumer electronics components, small aircraft, communication radar, and the medical industry.