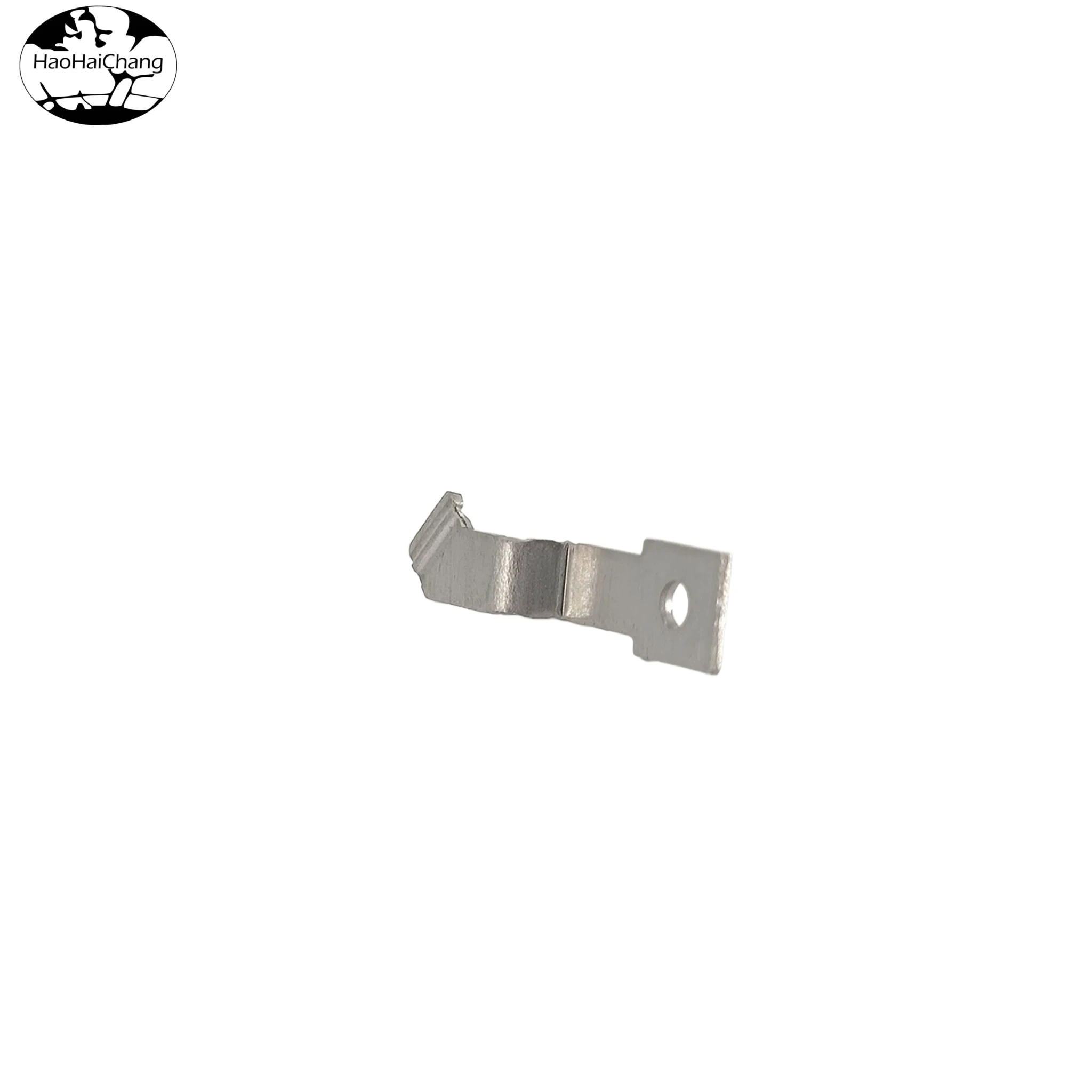

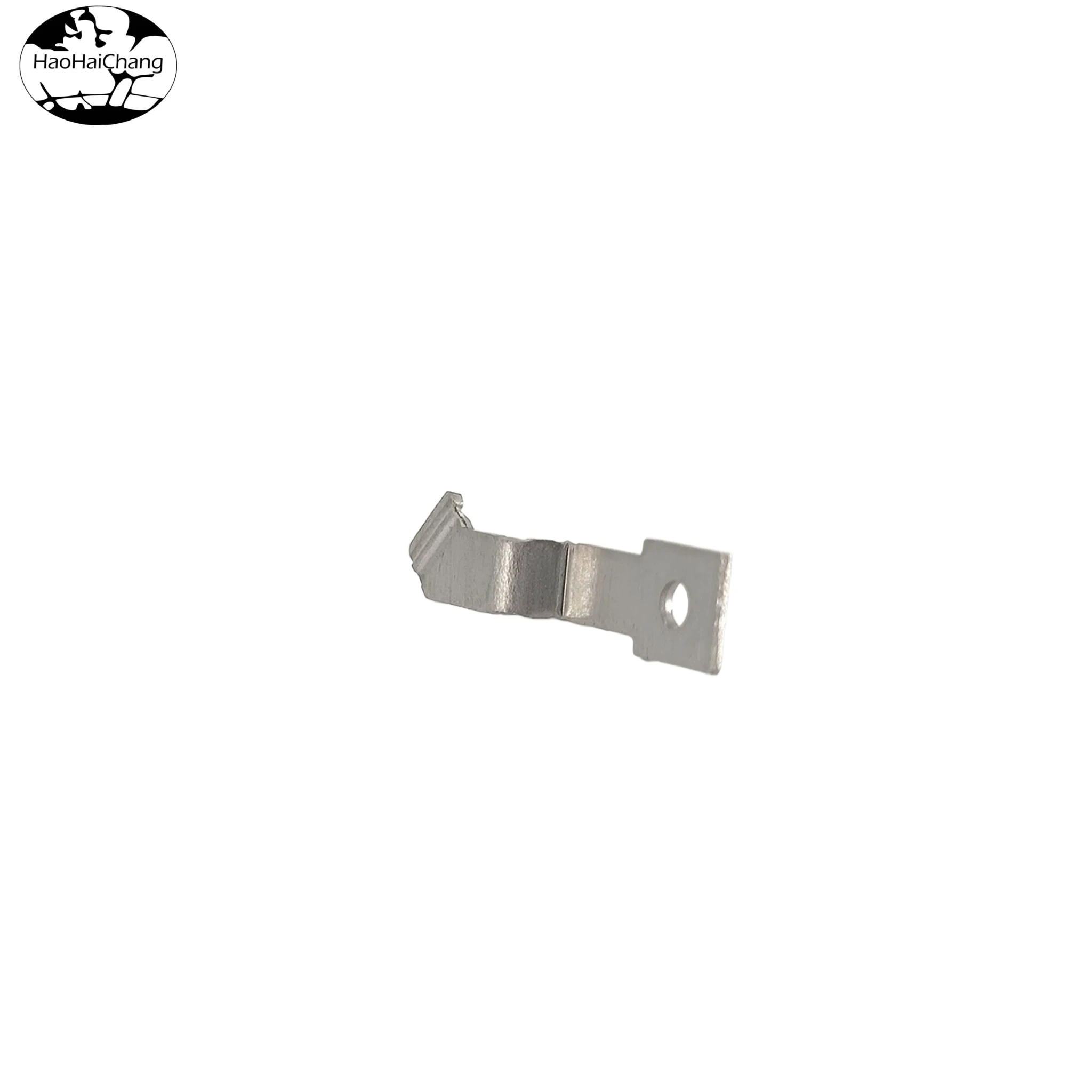

We are HHC Precision, a trusted manufacturer specializing in precision metal hardware components. Allow us to introduce our HHC-704 Angled Welding Lug with Mounting Hole, crafted from durable 430 stainless steel. Measuring 0.8×57×7.8 mm, this component is designed for the temperature control industry, ensuring dependable performance and precision.

Product Name | HHC-704 Angled Welding Lug with Mounting Hole |

Material Options | SUS301 SUS304 SUS316 |

Diameter Range | Φ2.0-Φ3.5 mm (mounting hole) |

Length Range | 20mm - 25mm |

Thickness | 1.0mm - 1.2mm |

Tolerance | ±0.01 mm |

Hardness | HV180-200 |

Color: | Silver metallic |

Manufacturing Process | Stamping, Bending, Punching, Cleaning |

Machining Capabilities | Stamping Threading Bending Welding preparation Surface finishing |

Applications | Metal structure welding, Equipment mounting brackets, Industrial machinery parts, Automotive components, Construction hardware |

Certifications | IATF16949:2016 ISO9001:2015 ISO13485:2016 ISO14001:2015 AS9131D |

Packaging Details | Packaged in plastic bags then placed in carton boxes or as per clients' specific requirements |

| Shipping Port | Shenzhen or Hong Kong |

| Production Lead Time | |

| Quantity (pieces) 1 - 10,000 | 10 days |

| Quantity (pieces) > 10,000 | To be negotiated |

| Customization Services | |

| Customized logo | Min. order 100(pieces) |

| Customized packaging | Min. order 100(pieces) |

| Graphic customization | Min. order 100(pieces) |